Social – Responsible Sourcing

Amplifying the sustainable impact together

At Hindustan Zinc, responsible sourcing is more than a business imperative — it is a cornerstone of our commitment to sustainable growth.

We actively embed sustainability considerations into our supply chain management, ensuring that environmental, social, and governance (ESG) principles guide our procurement decisions. Our approach involves meticulous assessment of risks and opportunities across our supplier network, ensuring informed decision-making and enhanced supply chain resilience. We actively collaborate with our business partners (BPs) to mitigate supply chain risks and drive sustainable sourcing practices. To reinforce these efforts, we have established a suite of comprehensive policies and guidelines, including our Supplier Code of Conduct, Sustainable Sourcing Policy, Supplier Sustainability Management Policy, and Supply Chain Strategy Document. These frameworks set clear expectations for ethical business practices while supporting responsible sourcing across our value chain.

By fostering strong partnerships and promoting responsible practices, we are building a transparent, resilient, and future-ready supply chain that delivers lasting value for our business, stakeholders, and the environment.

Material topics

M1 M2 M4 M5 M8 M10 M11 M12 M19 M20Capitals affected

Strategy linked

S3

S5

UN SDGs

Stakeholder affected

KEY FOCUS AREAS

- Lowering carbon footprint by introducing electric vehicles (EVs) and Liquified Natural Gas (LNG) vehicles

- Ensuring adherence to the Supplier Code of Conduct across the supply chain

- Developing local vendors to promote local procurement and reduce emissions

- Conducting ESG assessments for business partners to promote responsible practices

- Introducing alternative products to enhance safety and sustainability

- Rebuilding equipment to extend its lifespan and improve resource efficiency

SUPPLY CHAIN EXCELLENCE IN FY2025

768

Total commercial business partners (BPs) transacted; 56 added during the year

327

Local commercial BPs

66%

Local spend* (Rajasthan & Uttarakhand)

₹ 10,096 crore

Spent on critical tier 1 BPs

95%

Sustainable sourcing

19%

Of MSME spend**

49

Women-owned Businesses

*GST registered suppliers in the states of Rajasthan & Uttarakhand

**Excluding royalty

RESPONSIBLE SOURCING GOVERNANCE

We have established a robust governance framework to ensure responsible sourcing and compliance with globally recognised standards. Our Procurement Rulebook standardises the procurement process, supported by an effective Vendor Management System for streamlined supplier oversight. We align our approach with ISO 20400, the international standard for sustainable procurement, to enhance our sustainability practices. We conduct third-party audits aligned with international ESG frameworks to assess supplier performance. Additionally, we perform risk assessments, including evaluations for compliance with the Modern Slavery Act (MSA). Upon identification of any issues or discrepancies, we implement corrective action plans to address them. These measures reinforce our commitment to building a transparent, ethical, and sustainable supply chain ecosystem.

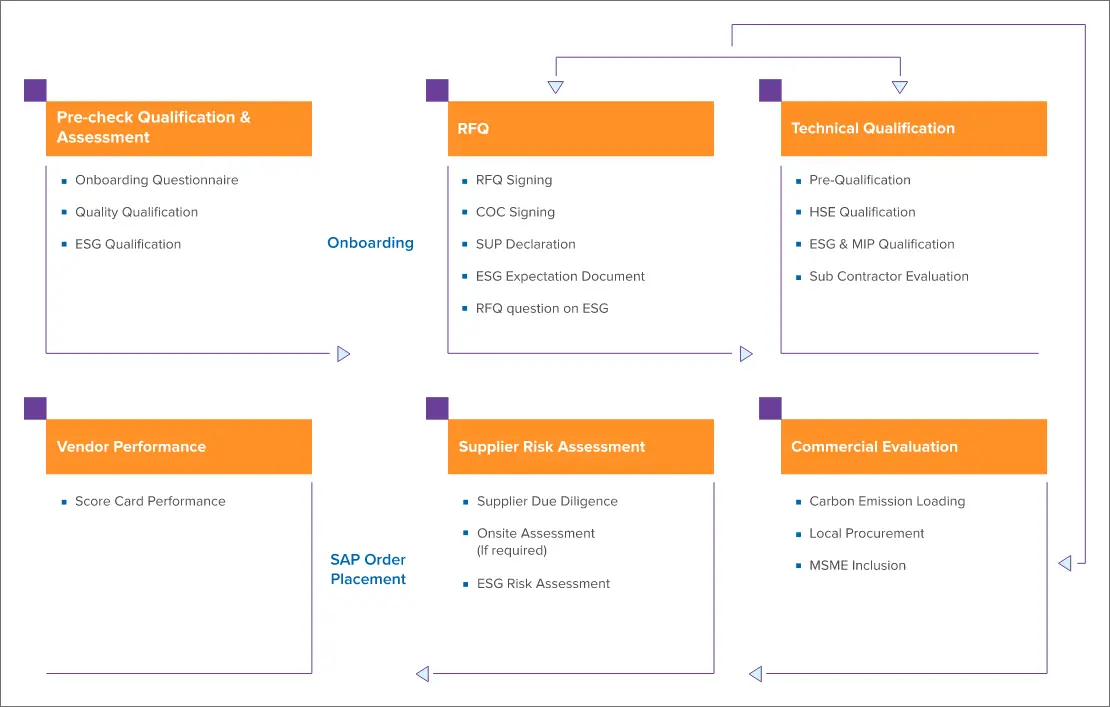

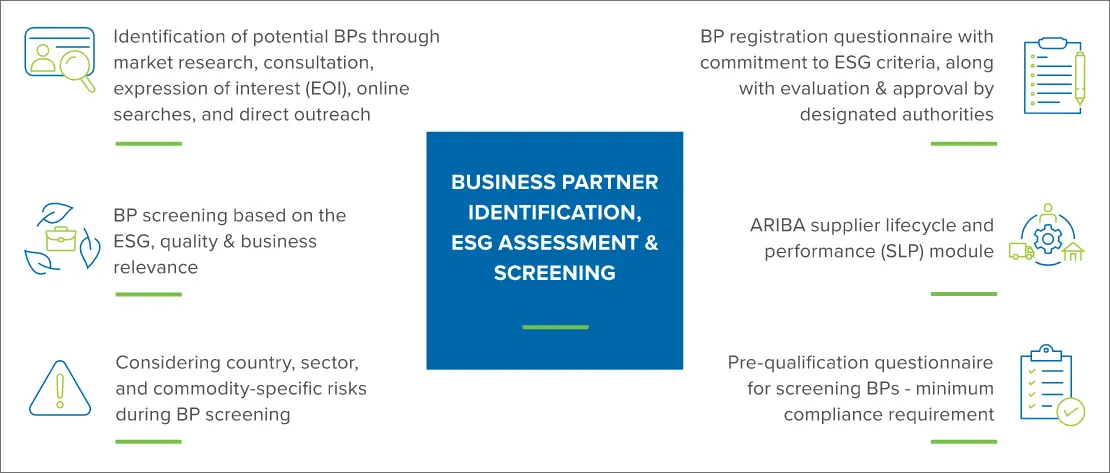

VENDOR MANAGEMENT AND ONBOARDING

Hindustan Zinc is committed to building a resilient, ethical, and sustainable supply chain that resonates with our core values and business objectives. To achieve this, we have implemented a structured process for identifying, assessing, and onboarding business partners to ensure they meet our standards for quality, compliance, and sustainability.

BP Monitoring

- Performance assessment against compliance and ESG criteria, with BP payments linked to adherence with safety and statutory obligations, and a penalty/incentive system in place to enhance productivity and safety across all locations

- Regular monitoring of data such as greenhouse gases (GHGs), water, climate & water risks, etc., for key contracts, covering safety, human rights and environmental compliance

- Regular contractor field safety audits (CFSAs) for on-site service contractors to promote health, safety, environment & social (HSES) governance practices

- Integrated performance module in ARIBA for tracking BP performance on quality and delivery, facilitating corrective actions, if necessary

SUPPLIER CODE OF CONDUCT AND POLICY

As part of our commitment to building a sustainable and ethical supply chain, we have a wide array of policies and guidelines designed to promote responsible sourcing. Aligning with our overarching commitment to sustainable sourcing, these policies articulate our clear expectations for our suppliers while supporting efforts to mitigate supply chain risks and elevate sustainability performance.

Supplier Code of Conduct

Our Supplier Code of Conduct is applicable to all business partners, including material suppliers and service partners. The code outlines the principles and minimum standards we expect them to uphold, thereby ensuring alignment with our values and sustainability goals. Strict adherence to this code is mandatory for all our business partners, reinforcing our commitment to integrity and responsible sourcing.

The code specifically addresses key aspects such as labour & human rights, health, safety & environmental sustainability, business integrity, prevention of unethical practices, grievance redressal mechanisms, climate change considerations, legal compliance, zero tolerance towards governance issues, and prohibition of insider trading. To further cascade the responsible practices, these principles are extended beyond our direct business partners to include their respective value chains as well.

This Code has been developed through collaboration with customers, suppliers, Group companies, and non-governmental organisations (NGOs). It signifies our resolve to uphold internationally recognised standards, including the fundamental conventions outlined by the International Labour Organization (ILO), the principles of the United Nations’ Universal Declaration of Human Rights, and prevailing industry norms.

In our continued commitment to promoting responsible business practices, we have recently revised our Supplier Code of Conduct. The updated version introduces additional clauses on psychological and psychosocial well-being, community engagement, ethical compliance, risk-based procurement, and quality assurance. These new provisions ensure that all our business partners not only maintain the highest levels of responsible business practices but also actively contribute to our shared goal of responsible sourcing and sustainability.

Sustainable Sourcing Policy

We ensure rigorous sustainability practices throughout our supply chain via a comprehensive sustainable sourcing policy. This policy establishes clear environmental and ethical standards for business partners. It outlines Hindustan Zinc’s efforts to mitigate HSE occupational risks, enforce a zero-tolerance stance on human rights violations, and promote the adoption of ESG principles. The Company’s approach includes conducting thorough supply chain risk assessments, fostering skill enhancement, ensuring transparency, and cultivating strong relationships with business partners through continuous improvement and digitalisation. We have also developed an ‘ESG Expectations Document’ serving as a definitive guide to align our business partners with our ESG standards.

SUSTAINABLE SUPPLY CHAIN

Supplier ESG Programme

At Hindustan Zinc, we are steadfast in our resolve to adopt best practices for a responsible value chain. We have made significant strides in integrating ESG principles across our supply chain, recognising the importance of aligning our business partners with our overarching sustainability goals.

Key Initiatives in FY2025

Vendor ESG evaluation

We circulated ESG assessments to 528 vendors to evaluate them against our ESG criteria

Carbon footprint reduction in supply chain

We have mapped our suppliers with carbon reduction targets, with 67% of our Tier 1 suppliers now committed to such targets

Business partner engagement

We actively engage with our suppliers through various initiatives. We organised ‘Business Partner ESG Connects’ with critical business partners to discuss sustainability practices and articulate our expectations

Business partner capacity building

As part of our capacity-building programme, we introduced the ‘Wednesday for Transition’ series in FY2024 and subsequently conducted nine training sessions in FY2025 to support our business partners in adopting ESG best practices

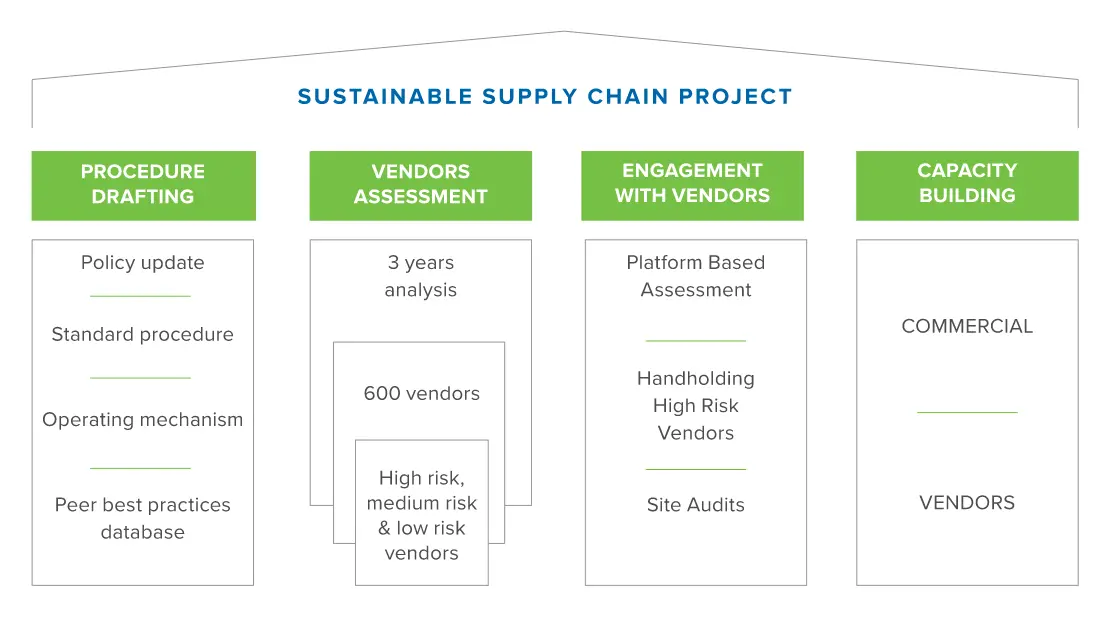

Advancing Supply Chain ESG Excellence

To further fortify our commitment towards a sustainable supply chain, we have partnered with a third party to advance our supply chain ESG programme through a comprehensive, end-to-end initiative. The initiative includes supplier risk evaluation, capacity-building workshops, handholding and support, and a systematic supplier engagement plan.

Key Aspects of Supply Chain ESG Programme

Critical business partner assessment

As a part of it, a thorough assessment will be conducted on 200 identified critical business partners to evaluate their compliance with ESG standards.

Feedback and support

Suppliers identified as low and medium-risk will receive constructive feedback aimed at improving their practices. Additionally, for the suppliers who do not meet Hindustan Zinc’s ESG criteria, the Company will provide end-to-end support to assist them in achieving compliance and enhancing their sustainability performance.

Capacity building

To align its supply chain with sustainability goals, Hindustan Zinc will organise capacity-building sessions for business partners. These sessions will focus on setting GHG targets, establishing water-related targets, and meeting other relevant ESG commitments. Furthermore, training will be provided for Hindustan Zinc’s internal commercial team to promote responsible sourcing and enhance their understanding of ESG principles.

Supplier engagement

A centralised database showcasing the best ESG practices from suppliers in the metals and mining sector will also be developed. This database aims to facilitate benchmarking among suppliers and promote peer learning and sharing of successful sustainability strategies.

Compliance

Hindustan Zinc is committed to regularly monitoring its supply chain through quarterly checks on high-risk business partners to ensure adherence to ESG standards. On-site assessments will be performed when necessary to maintain compliance and support continuous improvement.

EMBEDDING EFFICIENCY AND RESPONSIBILITY INTO SUPPLY CHAIN

Commercial Rule Book: Optimising Procurement

We have launched a comprehensive Procurement Rulebook to standardise and streamline our procurement processes. This framework provides clear guidelines for sourcing, contracting, vendor management, and requirement consolidation. Emphasising cost efficiency, transparency, and robust governance, the rulebook integrates mandatory ESG criteria and performance management into our procurement process. With best practices such as price discovery through auctions and effective vendor management, it is designed to enhance decision-making and ensure that all procurement activities are conducted ethically and efficiently. This initiative reinforces our commitment to building a resilient, responsible, and future-ready supply chain.

Alternative Product Development: Innovating for Efficiency and Safety

We have initiated the development of five alternate products to enhance efficiency, replace hazardous materials and improve cost-effectiveness. As a part of this, we have successfully developed an alternative product that replaces an inflammable material with a safer, non-inflammable alternative for the froth flotation process at our mills. This strategic enhancement has resulted in improved workplace safety and delivered substantial cost savings owing to the product’s enhanced cost efficiency.

Product Life Cycle Enhancement: Adding Value Through Refurbishment

At Rajpura Dariba Mine, we extended the life of key drilling equipment through a sustainable refurbishment initiative. Instead of replacing the machine, we restored it to near-new condition, significantly improving its performance and reliability. This cost-effective approach added two more years of use while reducing operational costs. The initiative paid for itself in just over two months and helped us avoid the environmental impact of disposal. It reflects our commitment to resource efficiency and long-term value creation.

Transition to Battery Electric Vehicles (BEVs) and Greener Fuels: Accelerating Clean Transitions

Supplementing the deployment of ten electric vehicle (EV) trucks with 55 MT capacity each and 180 LNG vehicles in our operations, we signed a new contract during the year to deploy 40 electric vehicle (EV) bulkers for calcine inter-unit movement with a contract duration of eight years. This initiative is a significant step towards reducing emissions compared to the previously used diesel bulkers. Additionally, it is expected to enhance safety and improve vehicle availability, further strengthening our commitment to sustainable and efficient operations.

Local Alternate Vendor Development: Fortifying our Foundations

We developed 18 local alternate vendors across key material categories to bolster supply chain resilience. This yielded significant benefits, including reduced dependency on single suppliers, improved cost control, and tangible support for the local economies.

Creating Local Impact, Optimising Supply Chain

A compelling illustration of our alternate vendor development approach is related to sourcing the high-density polyethylene (HDPE) pipes and fittings, where we onboarded two local vendors after 20+ years of reliance on a single original equipment manufacturer (OEM). This shift resulted in significant cost savings, reduced risks, and a boost in local employment in the Kaldwas and Nathdwara regions. Moreover, shorter transport distances with these local vendors also helped lower our carbon footprint.

SUPPLY CHAIN RISK ASSESSMENT

At Hindustan Zinc, we prioritise our brand value by consistently operating with integrity, transparency, and responsibility. To uphold these standards, we employ a strong three-step risk assessment framework designed to proactively identify and mitigate potential threats within our supply chain.

First-Party Risk Assessment

- As part of our onboarding process, all new business partners undergo an ESG assessment. Partners scoring below a stringent threshold of 50% are excluded from the business to ensure we engage only with responsible vendors

- Additionally, all business partners are subject to an internal desktop-based risk assessment, and vendors found non-compliant are promptly blocked to mitigate potential risks

- We maintain a strong internal system for managing mineral supply chain risks, including strict responsible sourcing protocols and guidelines for conflict-affected and high-risk areas (CAHRA). Red flags identified during assessments are reported to senior management, triggering enhanced due diligence and careful remediation

Second-Party Assessments

We conduct targeted on-site assessments to evaluate the operational practices of our strategic or critical business partners, ensuring their alignment with our expected standards.

Third-Party Due Diligence

To provide an additional layer of assurance, we engage independent third-party experts to conduct detailed assessments, reinforcing our compliance with international standards such as LME responsible supply chain guidance, the Modern Slavery Act, the Responsible Minerals Initiative, as well as our internal policies. The critical dimensions, such as financial health, governance, litigation and default risk, regulatory risk, reputational risk, and sustainability risk, are considered in the assessment.

Due Diligence trend

We have also partnered with a third-party for risk assessment that specifically focuses on evaluating ESG-related risks associated with our business partners, incorporating various standards like GRI, BRSR, ICMM, and CDP. The ambit of the assessment covers environmental issues, social concerns, and modern slavery. Suppliers identified as high risk based on the assessment outcomes are required to undergo on-site assessments.

Corrective Actions

BPs identified as high risks are required to provide their corrective action plans. If they fail to improve within a set timeframe of one year, they are excluded from further business.

REINFORCING SUPPLY CHAIN WITH DIGITALISATION

Streamline Procurement with E-Commerce Buying

In order to streamline our procurement, we have partnered with an e-commerce platform for miscellaneous procurement for admin, HR, and gifting requirements across the organisation. This will empower teams with expeditious and hassle-free access to a wide array of products and enable faster order placement and delivery. Additionally, this will also offer us competitive pricing, ensuring better cost management, total transparency, and control.

Business Partner Grievance Mechanism

Hindustan Zinc maintains a dedicated Business Partner Grievance Portal to ensure prompt, efficient, and effective grievance resolution. A grievance committee with predefined escalation procedure has been established to ensure timely tracking and resolution, facilitated through automated emails and updates.

Vendor Zone & Information Portal

The Company offers a dedicated vendor zone on the website, serving as a platform for business partners to access the supplier information portal and e-learning training module on the ARIBA network. This resource provides comprehensive guidance on new supplier onboarding, along with helpful informational guides. The supplier training e-module includes easy-to-follow video guides to assist suppliers in comprehending Hindustan Zinc’s Code of Conduct, ESG expectations, and various processes such as auctions, invoice creation, and supplier profile management.

Supplier Code of Conduct Video Training Module

Hindustan Zinc has developed a training guide for its Supplier Code of Conduct, which is followed by an assessment. All business partners are required to complete the training and assessment, thereby formally confirming their agreement with Hindustan Zinc’s Code of Conduct.