Accelerating Momentum Embracing Opportunities... ...With Metals That Matter

This is how we accelerated momentum in FY 2025

Record production

1,095 kt

Mined metal 1%

1,052 kt

Refined metal 2%

Crossed 13 Mnt metal reserves

For the first time since underground transition

29.6 Mnt

Overall metal reserves and resources4-year low zinc cost of production

US $ 1,052 per tonne

6%

Launched Asia’s 1st Green Zinc “EcoZen”

75%

lower carbon footprint vs industry average2nd best financial performance

₹ 34,083 crore

Revenue 18%

₹ 17,465 crore

EBITDA 28%

₹ 10,353 crore

Profit after tax 33%

World leader in sustainability

#1

in Metals and Mining sector at S&P Global Corporate Sustainability Assessment (CSA) 2024 for the 2nd consecutive yearc.13% in FY 2025

Overall renewable power usageDelivered superior return to shareholders

₹ 198.60 per share

delivered total shareholder returns; 13x of NIFTY 50 returns and 7x of Nifty Metal index returns#3

under Nifty Metal Index based on market capitalisation of ₹ 1.95 lakh croreAmong the highest dividend yield companies in the country at c.5.6%

Among the top 10 wealth creators in the Nifty 200 Index

Hindustan Zinc at a Glance Leading the future of sustainable mining and metals

Hindustan Zinc, a Vedanta Group company, is the world’s largest integrated zinc producer and among the top 5 silver producers globally. We are a global leader in critical minerals and metals, with one of the largest and most diversified portfolios. We are recognised globally for our scale and operational excellence, technological and innovation capabilities, and pioneering sustainability efforts.

Our Group Structure

63.42% Vedanta Limited

27.92% Government of India

8.66% Public

SHAREHOLDING

HINDUSTAN ZINC LIMITED

SUBSIDIARIES

HZAPL

Hindustan Zinc Alloys Private Limited (HZAPL)

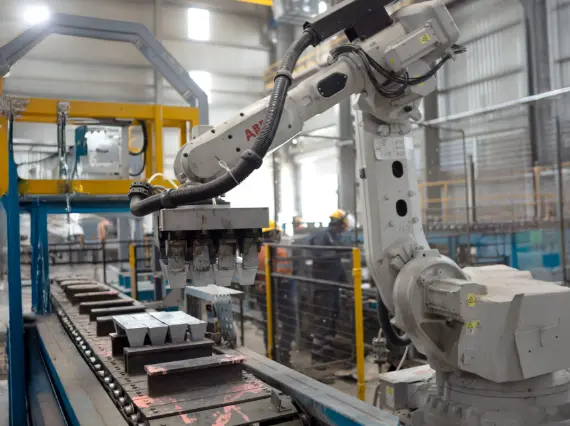

Engaged in manufacturing zinc alloys aimed at meeting domestic demand and expanding our value-added portfolio.

VZF

Vedanta Zinc Football & Sports Foundation (VZF)

Operates all our sports initiatives, including Zinc Football Academy, an AIFF 3-star Elite Academy, and community schools to nurture local talent along with education.

ZIF

Zinc India Foundation (ZIF)

Our not-for-profit arm for implementing community development and environmental projects, with a focus on tribal villages.

HZFPL

Hindustan Zinc Fertilisers Private Limited (HZFPL)

Establishing a 510 ktpa DAP/NPK fertiliser plant to utilise in-house sulphuric acid and reduce India’s import dependency.

HESPL

Hindmetal Exploration Services Private Limited (HESPL)

Focuses on identifying and developing high-potential mineral assets through advanced exploration technologies to enhance our long-term resource growth.

Note: Vedanta Limited has further reduced its stake to 61.84% through a bulk sale in June 2025, increasing the public shareholding to 10.24%.

BUSINESS SNAPSHOT Integrated capabilities, future-ready portfolio

OUR INTEGRATED OPERATIONS

PRODUCTS AND APPLICATIONS

Zinc

827 kt Production volume

₹ 21,887 crore Revenue

Lead

225 kt Production volume

₹ 4,227 crore Revenue

Silver

687 MT Production volume

₹ 6,130 crore Revenue

Message from the Chairperson

As I look back on the year gone by, I feel immense pride in how Hindustan Zinc is not only one of the largest but has also continued to evolve as India’s most innovative and sustainable mining and metals leader.

Priya Agarwal Hebbar

Q&A with CEO and WTD

We recorded the highestever mined metal production of 1,095 kt, up 1% over the previous year, and refined metal production of 1,052 kt, up 2%

Arun Misra

CFO's Statement

FY 2025 marks a milestone year in Hindustan Zinc’s legacy of financial excellence.

Sandeep Modi

INVESTMENT CASE Resiliently built. Strategically positioned.

STRATEGIC PRIORITIES Building a resilient, future-ready metals business

Business Excellence Drivers

KEY PERFORMANCE INDICATORS Accelerating momentum across the years

In a year marked by economic, currency and commodity price volatilities, Hindustan Zinc ensured disciplined investments and fiscal prudence to strengthen efficiency levers. Amidst firm commodity prices, our efforts to enhance volumes, increase by-product sales and undertake strategic hedging contributed to healthy topline growth. We achieved the lowest cost in four years, supported by systemic operational efficiency initiatives, higher domestic coal and renewable energy usage, and softened coal and input commodity prices. This resulted in robust profitability growth. With a fortified liquidity and balance sheet position to maintain an investment-grade credit rating.

Environmental, Social & Governance

Hindustan Zinc led with impact in FY 2025, ranking as the world’s most sustainable metals & mining company in the S&P Global CSA 2024. We achieved several of our ambitious ESG goals, including GHG emission reduction and positive social impact. We entered agreements to raise RE share to 70%, aiming to achieve Net Zero emissions by 2050.

SUSTAINABILITY AT HINDUSTAN ZINC Progressing on our sustainability commitments

At Hindustan Zinc, sustainability is a core factor influencing our long-term growth strategy. Guided by our ‘Zero Harm, Zero Waste and Zero Discharge’ vision, we are tangibly progressing towards a sustainable future, aiming for the SBTi-validated target of Net Zero by 2050 or sooner. We are actively reducing our carbon footprint, optimising resource usage, nurturing natural ecosystems, and prioritising social responsibility and operational excellence, ensuring sustainable development for generations to come.

Environment Stewarding nature’s wealth for a greener tomorrow

Social - People Igniting our people’s potential

Social – Health and Safety Committed to a responsible journey towards zero harm

Social – Corporate Social Responsibility Advancing two decades of shared value

Social – Responsible Sourcing Amplifying the sustainable impact together

Governance Committed to highest standards of governance

Here’s the Scoop

From on-ground impact to inspiring initiatives, our YouTube videos bring our journey to life. Watch how our people, purpose, and progress shaped the year – one story at a time. Each video captures a milestone, a movement, or a moment that mattered. Dive in to experience the energy, commitment, and vision that defined our year.

Meet the #WomenInZinc

– trailblazers who continue to break barriers and redefine leadership in the metals and mining industry. From India’s first woman underground mine manager to the nation’s first and second all-women underground rescue teams, their journey is a testament to resilience and excellence. With 25% gender diversity in 2025, we are dedicated to fostering an equitable workplace – one where every voice is valued and opportunities are limitless.

Women of Valor | Strength in every stride, power in every role.

– from the depths of the earth to the heights of leadership, these women are redefining what it means to lead in metals and mining. Hindustan Zinc is proud to have India’s first all-women underground mine rescue team, which secured global recognition by securing second place at the International Mines Rescue Competition 2024 in Colombia. At Hindustan Zinc, inclusion isn’t just a commitment – it’s a movement.

Case Study

DIGITALLY TRANSFORMING ZINC SALES & LOGISTICS AT HINDUSTAN ZINC

PROBLEM STATEMENT

In the traditionally structured metal industry, sales of zinc and silver were often managed through manual, opaque processes that limited real-time price discovery and created barriers for smaller or remote buyers. This affected customer participation and restricted the company’s ability to dynamically link premiums to market rates.

Expanding Downstream Product Portfolio through Alloys

PROBLEM STATEMENT

As a commodity-based company, Hindustan Zinc’s topline is majorly linked to the LME and LBMA price cycles. So, it is imperative that we should transition from a commodity-based company to a product-based company by enhancing our downstream product portfolio.

Balancing ESG with Fiscal Prudence through Renewable Energy

PROBLEM STATEMENT

As the focus of the world is shifting towards green energy, it becomes imperative for a global sustainability leader like Hindustan Zinc to lead the sector by becoming early-adopter of utilisation of renewable energy for metal production, significantly decreasing the global footprint of one of the world’s largest metal portfolios.

Optimising Smelter Consumables through Digital Technology

PROBLEM STATEMENT

Our smelters utilise various consumables such as zinc dust, sodium sulphate, polymeric aluminium trihydrate (PAT), lime, and soda ash, etc., which are vital for maintaining chemical reactions, controlling processes, and ensuring the smooth operation of our smelting activities. It is crucial to optimise the utilisation of such consumables, which constitute a significant portion of our overall smelting spend base.

OUR REPORTING SUITE Leading Reporting Practices

We are committed to providing information ethically and transparently to our stakeholders. We ensure this through our diverse reporting suite, which ensures clear and comprehensive disclosures.

OUR REPORTING SUITE INCLUDES THE FOLLOWING

Awards & Recognitions

- Ranked 1st in the Metals & Mining sector for the 2nd consecutive year in the S&P Global Corporate Sustainability Assessment 2024

- Placed in Top 1% in S&P Global Sustainability Yearbook 2025, featuring for the 8th consecutive year

- Integrated Annual Report 2023-24 and Sustainability Report 2023-24 ranked 1st globally in Materials category with Platinum in LACP Vision Awards 2023-24. Integrated Annual Report was also recognised as the Most Creative Report Worldwide for 2023-24

- India’s First Gen AI for Annual Reports ‘Zincky’ has been recognised globally bagging a Platinum at AVA Digital Awards 2025

- Prestigious awards of ‘Best Risk Practice’ and ‘Masters of Risk in ESG’, in large cap category at the India Risk Management Awards by CNBC TV18

- Zinc Football Academy was recognised as the “Sports Academy of the Year” at the Sports India Awards 2024, and was awarded a 3-star rating by All India Football Federation (AIFF) in the Academy Accreditation 2024-25

- Recognised as an Employees’ Choice Workplace at the W.E. Matter Global Employees’ Choice Awards 2024

- India’s First All Women Underground Mine Rescue Team secured 2nd place at the 13th International Mine Rescue Competition, Columbia

Foundations for Sustainable Growth

Business Model Business model built for tomorrow’s opportunities

Stakeholder Engagement Responding effectively to stakeholder needs

Materiality Creating value using materiality compass

Risk Management Mitigating risks and harnessing opportunities to drive sustainable growth

External Environment Positioned to lead and embrace expanding opportunities

The Year As It Was

Large scale, low cost, irreplaceable asset base with mine life of 25+ years

Large-scale operations with tier-1 assets and product portfolio

- World’s largest integrated zinc producer and among the top 5 silver producers with world-class, strategically-located mining and smelting assets

- Crossed 13 Mnt of metal reserves first time since underground transition (3x growth over FY 2020 levels on net of production basis) and continue to maintain 25+ years mine life with a focus on ongoing replenishments supported by innovative technologies and advanced geophysics

- Diversified, customer-centric product portfolio with c.22% value-added products, strong domestic presence of about 77% in primary zinc market share and growing presence in over 40 countries

Global cost leadership

- First decile in the global zinc mining cost curve and first quartile in the global zinc smelting cost curve

- Sustainable cost reduction powered by integrated operations, economies of scale, structural cost reduction initiatives, automation and digitalisation

- Growing renewable energy share insulates power cost from commodity price variations

US $ 1,052(₹ 88,960) per MT

Zinc COP29.6 Mnt

Total Metal R&R25+ years

Mine Lifec.22%

Value-added PortfolioInvested in metals relevant for energy transition

Offering metals essential for societal progress

- Promoting everyday base metals in enabling a low-carbon, sustainable future

- Evolve into a multi-metal, future-enabling enterprise, aligned with India’s critical mineral security vision; exploring high-potential minerals like copper, lithium, nickel, cobalt, potash, rare earth elements (REE) and gold, critical for electric vehicles (EVs), semiconductors, and clean technologies

- Through our Hindmetal Exploration Services Private Limited, we won a Tungsten block in Andhra Pradesh in FY 2025. In May 2025, we further strengthened our critical mineral portfolio by winning the Potash block in Rajasthan and Rare Earth Elements block in Uttar Pradesh

Zinc: a critical metal for daily use and future technologies

- Essential for galvanising steel, supporting clean energy infrastructure and enabling EV manufacturing

- Usage in 3D-printed automotive parts, UV-resistant coatings for modern buildings, and public health, with zinc oxide nanoparticles used to purify water and create germ-resistant cleaners for hospitals

- Ensures longer life of the solar panels and wind turbines by preventing corrosion

- Zinc-based batteries offer a low-cost, long-life and sustainable alternative to the lithium variants, being non-toxic and effective across a wider temperature

Silver catalysing the green economy

- Silver’s role is extending beyond precious metal to a strategic green metal for powering the transition to a low-carbon, high-tech world – applications spanning electronic systems, including telecommunications, infrastructure and EVs

- Its unmatched conductivity makes it highly effective in the solar energy industry (for photovoltaic cells) and other sectors targeting carbon footprint reduction

Ideally positioned to capitalise on India’s growth

Resilient economy and steel industry outlook

- India recorded a GDP growth of 6.5% during FY 2025, driven by expansion in infrastructure, construction, automotive and manufacturing sectors.

- With the government’s sustained focus on infrastructure development, including smart cities, railways, highways and airports, the International Monetary Fund projects GDP growth to remain above 6.5% over the next 3-4 years.

- A booming economy continues to propel steel demand in India; the world’s second-largest steel producer saw annual crude steel production growing at a compounded c.10%, against a flat trend globally.

- To sustain economic growth, India targets decision-making steel capacity to 300 Mtpa by 2030 with equal emphasis on energy transition (target to add 500 GW of non-fossil fuel-based energy by 2030 and become net zero by 2070).

Hindustan Zinc positioned for growth

- These factors are set to almost double the domestic zinc demand for steel galvanisation and silver demand by a multifold to support the energy transition.

- Our global market-leading position in zinc, with about 77% share in the domestic primary zinc market, positions us to benefit from India’s growth.

c.77%

Domestic primary zinc market share250 ktpa

New integrated refined metal capacity expansion with associated mining capex with an investment of c.₹12,000 croreRobust financial profile and strong balance sheet

Proven financial foundation

- Consistently delivered phenomenal performance across all financial parameters, supported by operational efficiencies and cost optimisation strategies

- Industry-leading EBITDA margin of c.50%, irrespective of the commodity price cycles and market volatilities

- Over five decades of expertise in commodity markets and a strong leadership suite, enabling strategic decision making and facilitating innovation to improve operational consistency

Healthy balance sheet

- Consistent AAA investment-grade credit rating by CRISIL, reflecting stable net debt position and robust free cash flow, enabling cheaper financing

- Strong cash and cash equivalents supporting consistent dividend payments and staying opportunistic for organic and inorganic growth

₹ 13,326 crore

Net worth50%

3-year average EBITDA margin₹ 1,169 crore

Net Debt₹ 10,926 crore

5-year average pre-growth capex free cash flow from operationsInvestments in high IRR Projects driving strong shareholder returns

Disciplined capital management

- Strategic investment in high IRR projects (fertiliser plant, roaster, zinc alloy plant and hot acid leaching plant), with innovative measures to scale production, profitability and achieve the sustainability targets

- Industry-leading returns driven by efficient capital allocation, process rationalisation and targeted operational efficiencies and cost optimisation strategies

- Lower capex costs being based in India, among the world’s cheapest labour and power market

Sustainable value creation and delivery

- Unique global positioning and expertise in navigating the market volatilities ensures resilience, agility and maximisation of value creation

- Efficient project execution via trained partners and teams, detailed planning, and global expert collaborations

- Delivering strong shareholder returns through consistent growth and dividends in line with our dividend policy

143%

5-year average dividend payout₹4,430 crore

Capex utilised in FY 2025₹1,95,167 crore

Market capitalisation (among the top 3 in the Nifty Metal index) as on March 31, 2025c.68%

Total Shareholder Returns (among the top 10 in the Nifty 200 index)73%

Return on Equity58%

Return on Capital EmployedESG excellence, investing in sustainable future

ESG with fiscal prudence

- Integrating ESG principles into our growth and financial strategy

- Expanding use of renewable energy and energy-efficient vehicles (battery-electric, LNG, and electric-based), helping optimise costs along with advancing decarbonisation

- Launched Asia’s first low-carbon zinc, EcoZen, which can fetch better premiums

Business sustainability through responsible operations

- Industry-defining initiatives to achieve ambitious ESG goals 2030

- Focus on circular economy and economically gainful waste utilisation and metal recovery through our recycling business

- Foraying into zinc-based batteries through strategic partnerships to catalyse the global energy transition. Hindustan Zinc has signed an MoU with AEsir Technologies for advancing in zinc-based batteries

2.3million

Beneficiaries across 2,362 villages from sustained CSR initiativesc.13%

Share of renewable energyESG excellence, investing in sustainable future

Related risks

KPIs tracked

- Total mineral resources & ore reserves (R&R)

- Overall mine life

Capitals deployed

We aim to intensify and enhance the efficiency of exploration drilling to add mineral resources and upgrade existing resources to reserves. It is critical to driving efficiency and sustainability of mining operations, and will ensure replenishment, leading to 25+ years of mine life. Given that our deposits are open in depth and have lateral extensions, we do intensive drilling and expand the mineral resource base, while deploying innovative methods and technologies.

Actions taken in FY 2025

- Increased total ore reserves to 189.1 Mnt (net of production of 16.3 Mnt), as against 175.1 Mnt at the end of FY 2024; total exclusive mineral resource stood at 264.1 Mnt

- Surpassed 13.1 Mnt of metal reserves for the first time, adding 1.7 Mnt net of production

- Combined R&R estimate stood at 453.2 Mnt (29.6 Mnt of zinc-lead metal and 808.4 million ounces of silver) with 25+ years mine life

- Participated in auctions of critical mineral blocks and won Ballepyllum Tungsten & Associated Minerals Block in Andhra Pradesh. Also, won two more composite licenses in May 2025 – Potash Block in Rajasthan and Rare Earth Elements Block in Uttar Pradesh

Way Forward

Expansion |

Diversification |

Technology Upgradation |

|

|---|---|---|---|

FY 2026 |

|

|

|

FY 2027 |

|

|

|

FY 2030 |

|

|

|

Expansion of Capacities

Related risks

KPIs tracked

- Mined metal production

- Refined metal production

- Refined silver production

Capitals deployed

Ensure ongoing investment in capacity expansion (organic and inorganic) and operational excellence, aiming to be the world’s largest and most admired zinc, lead and silver company. Over the next 5 years, we will commit a capex of ₹ 25-30k crore towards expanding refined metal capacity from 1.2 to 2 million tonnes.

As a key milestone in this long-term roadmap, Hindustan Zinc’s Board approved in June 2025 a major expansion project to enhance our integrated refined metal capacity by 250 ktpa. This initiative, involving an investment of c.₹ 12,000 crore, marks a bold step towards realising our 2030 vision.

This expansion includes establishing a new smelter with 250 ktpa capacity in Debari, along with a leaching and purification plant, a cell house, and an additional 160 ktpa roaster. With these additions, our overall metal capacity will rise to 1,379 ktpa, while mining capacity will increase to 1,510 ktpa to align with the smelting capabilities. The plan also includes concentrator expansion projects and several debottlenecking projects to boost capacity and enhance mining and milling infrastructure.

End-to-End Outsourcing

with EPC Partner

Project Timeline

36 months from the zero date

Project Cost

Overall project cost of c.₹ 12,000 crore

*Considers debottlenecking planned in FY 2026

Actions taken in FY 2025

- Achieved superior production performance:

- Highest-ever mined metal and refined metal of 1,095 kt and 1,052 kt, respectively

- 687 MT silver, with the fumer plant ramping up to 50% capacity utilisation in March 2025

- Total mine development of 95.9 km, with Zawar and Rampura Agucha Mines achieving their highest-ever mined metal production of 210 kt and 568 kt, respectively

- Initiated projects to drive the next phase of growth and expand production capabilities at mines, including:

- Placed order for infrastructure development and commenced excavation work for portal construction at Bamnia Kalan Mine

- Enhanced ventilation capacity at Sindesar Khurd from 1,350 to 1,950 m3/sec

- Commenced a new portal at Zawarmala to ramp up the production to 2 Mtpa

- Commissioned a dry tailing plant at Rajpura Dariba Mine and began excavating the Maa Annapurna Portal and Decline for a new mine entry, which will allow the use of high-capacity equipment

- Conceptual designing and detailed engineering studies are ongoing for 2x growth, including zinc, lead and silver, and tailings recycling

Way Forward

| Capacity Expansion | Technology, Innovation and Resource Optimisation | |

|---|---|---|

FY 2026 |

|

|

FY 2027 |

|

|

FY 2030 |

|

|

Strengthening Cost Leadership

Related risks

KPIs tracked

- Zinc cost of production

- % Domestic Coal

- % Renewable Energy

Capitals deployed

We aim to remain among the lowest-cost zinc producers globally, staying in the first decile of the global zinc mining cost curve to support our future growth strategy. This will be achieved through continual volume expansion, grade improvement, innovation, automation, digitalisation, and investment in renewable energy.

Actions taken in FY 2025

- Achieved a 4-year low zinc cost of production (COP) of US $ 1,052/MT through efforts like cost optimisation, volume enhancement, RE usage, operational efficiencies, better grades, higher recoveries, and digital improvements, leading to cost savings of c.US $ 65/MT

- Reduced energy costs by:

- Sourcing c.13% of total power requirement from renewable energy including a 530 MW round-the-clock RE power delivery agreement at a cheaper fixed rate, insulated from inflation and exchange rate fluctuations

- Improving efficiency and the percentage of Indian coal in the blend, which reduced power costs by 4%

- Undertook various alternative fuels innovations, thereby pushing operational efficiencies

- Smelter recovery improvement through various initiatives like fumer plant, etc.

- Focused on reducing equipment cost, increasing productivity, and rationalising deployment and improving utilisation of machines underground

Way Forward

| Cost Optimisation | Renewable Energy Transition | |

|---|---|---|

FY 2026 |

|

|

FY 2027 |

|

|

FY 2030 |

|

|

Building a Diversified Product Portfolio

Related risks

KPIs tracked

- VAPs addition

- Share of VAP

Capitals deployed

We aim to meet the evolving customer needs through ongoing product suite expansion, with a focus on innovative value-added products (VAP). Furthermore, we invest in nurturing and skilling our employees to ensure their readiness and responsiveness to customers.

Actions taken in FY 2025

- Launched Asia’s first low-carbon green zinc, EcoZen, having a carbon footprint of less than 1 tCO2e per tonne of zinc produced, about 75% lower than the global average

- Achieved the highest-ever annual VAP sale of 179 kt (including zinc dust), increasing VAP share to 22% from 20% in FY 2024

- Successfully conducted Zinc Aluminium Magnesium Alloy (ZAM) trials with new customers, some of which are established, while others are in the process

- Partnered with US-based AEsir Technologies to innovate the battery storage space through Nickel Zinc batteries, supporting the global energy transition

Way Forward

| Product Development | Market Expansion and Strategic Efforts | |

|---|---|---|

FY 2026 |

|

|

FY 2027 |

|

|

FY 2030 |

|

|

Progressing Towards a Sustainable Future

Related risks

KPIs tracked

- Metal recovery

- Specific water consumption

- Specific energy consumption

- Water recycled

- Waste recycled

- GHG emission

- Renewable power capacity

Capitals deployed

Sustainability will continue to be a key growth driver, enabled by our ambitious Sustainable Development Goals 2025. We aim to become a nature-positive company with sustained actions to reduce our carbon footprint and advance our circular economy goals. Our efforts also focus on fostering a healthier and safer workplace, promoting responsible sourcing, encouraging diversity and inclusion, supporting community development, etc.

Actions taken in FY 2025

- Sustainability will continue to be a key growth driver, enabled by our ambitious Sustainable Development Goals 2025. We aim to become a nature-positive company with sustained actions to reduce our carbon footprint and advance our circular economy goals. Our efforts also focus on fostering a healthier and safer workplace, promoting responsible sourcing, encouraging diversity and inclusion, supporting community development, etc.

- Utilised 15.5 kt of biomass for power generation, reducing our carbon footprint

- Deployment of 180 LNG trucks across locations for inter-unit and finished goods transfer in partnership with GreenLine

- Deployed three EV charging stations for our EV trucks for seamless inter-unit transport

- Commissioned a 4,000 KLD water treatment plant at Rampura Agucha Mine

- Biodiversity management plan finalisation with the International Union for Conservation of Nature (IUCN) in the third year of engagement

Way Forward

| Carbon and other emission reduction | Other efforts | |

|---|---|---|

FY 2026 |

|

|

FY 2027 |

|

|

FY 2030 |

|

|